AdBlue Exhaust Treatment

Vehicles fitted with AdBlue exhaust gas treatment systems are now the norm in PSV workshops since the Euro VI legislation came into force in 2015. The technology, which reduces nitrogen oxide (NOx) emissions by over 90%, has become increasingly important as low emission zones continue to be introduced across the UK. NOx emissions have been a target for regulators for some time due to the gas being a primary cause of respiratory health disorders and damage to the environment. According to data from the Royal College of Physicians, NOx emissions contribute to around 40,000 deaths, six million sick days and an overall social cost of £22.6 billion to the UK each year.

AdBlue is a brand owned by the German Association of the Automotive Industry (VDA) and is the most recognised form of diesel exhaust fluid (DEF) produced in accordance with ISO 22241 specifications. Consisting of a mixture of 32.5% synthetic urea and 67.5% deionised water, DEF is injected into a vehicle’s exhaust gas flow via selective catalytic reduction (SCR). When added to the high temperature gases, the urea is converted into ammonia through thermolysis and hydrolysis. As it enters the catalytic converter, the ammonia reduces the NOx to water and nitrogen. Urea is highly soluble in water and can therefore be added to the exhaust gas in the liquid form of DEF which can be precisely metered.

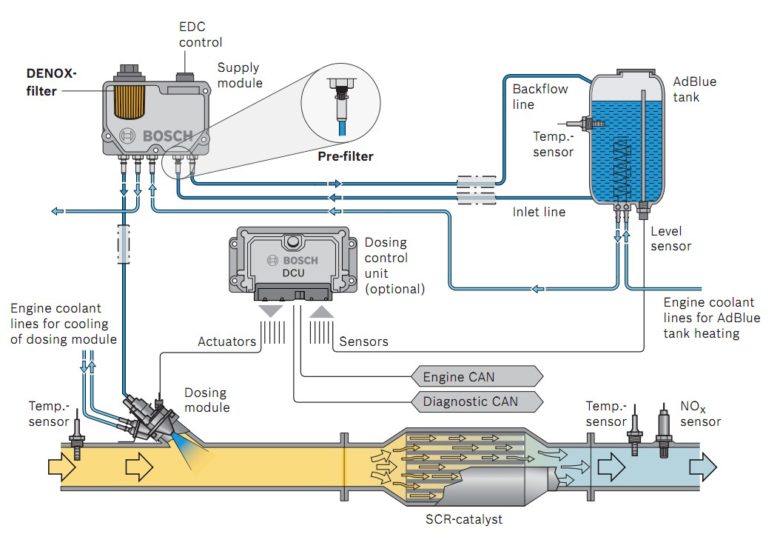

For PSV applications, the Bosch Denoxtronic exhaust treatment system has become one of the most widespread SCR systems on the market. The modular Bosch SCR system consists of a supply module located in the fuel tank which delivers the DEF with the required pressure into a dosing module via a solenoid membrane pump. The dosing module precisely controls the quantity of DEF and handles its atomisation and distribution in the exhaust pipe. A control unit housed in the dosing module manages the model-based calculation of the required dosing quantity according to a predetermined strategy.

As with all emissions system components fitted to buses, their correct and efficient operation is essential to ensure vehicles run in compliance with emissions legislation. With this in mind, Bosch has also introduced KTS Truck, a modular diagnostic system which provides PSV operators with an entry point into Bosch bus diagnostics. Connected via USB or Bluetooth, KTS Truck combined with Bosch ESI[tronic] 2.0 Truck software, facilitates comprehensive diagnosis, troubleshooting and fault searches and solutions. The software also contains technical information for a wide range of vehicles, including wiring diagrams, service and repair instructions and system information.

Imperial Engineering is an authorised Bosch distributor and is pleased to support operators with technical advice and guidance. For further information, please contact us.