The PSV sector is leading the way in the UK’s Net Zero journey as Europe’s largest zero emission (ZEV) bus market by volume, with almost half of the units entering service last year featuring electric or hydrogen drive systems. According to the latest SMMT data, strong investment by operators in decarbonising their fleets has seen ZEVs account for 45% of new single and double decker bus registrations in 2023. Within the ZEV segment, the UK is also leading Europe in electric bus deployment, with 1,206 e-buses registered in 2023, based on figures from Chatrou CME Solutions.

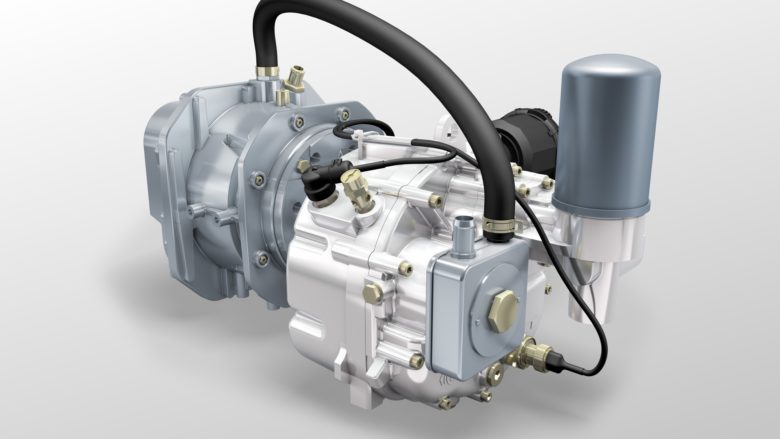

Although e-buses are visually similar to conventional diesel buses on the outside, on the inside e-buses are entirely different in terms of producing the compressed air that provides the energy source for the air brakes, pneumatic suspension and door system. While diesel buses use engine-driven air compressors, e-buses are equipped with separate electrically-driven screw or vane compressors. Known as ‘e-compressors’, these systems include a compressor, electric drive motor and inverter. A number of OEMs including Gardner Denver, Hydrovane and Knorr-Bremse supply bus manufacturers with e-compressors.

Unlike diesel-driven compressors that are lubricated and cooled by the engine’s oil circuit, e-compressors feature a standalone lubrication system. Also, in contrast to conventional compressors which are supplied with clean air from the engine air filter, e-compressors take in the ambient air through an air filter. Some e-compressors also feature ECU-based air dryer and compressor control functions. These systems require regular oil and filter changes in line with the compressor manufacturer’s recommendations and a vehicle’s duty cycle to deliver consistent performance and ensure the service life of the system. Conventional compressors, costing around £500, require minimal maintenance and are designed to provide an average service life of five years. In comparison, e-compressors can cost up to ten times more to replace.

Leading bus parts distributor, Imperial Engineering, has seen an increase in demand for replacement e-compressors as e-bus registrations continue to grow, despite the fact that these systems are intended to have a longer lifespan in comparison to engine-driven compressors due to their design and less internal moving parts, providing they are properly maintained. Concerned that this is causing operators unnecessary expense, Imperial Engineering has investigated premature e-compressor failure and found that major contributors include excessive oil consumption. This leads to bearing and rotor damage, causing the compressor to run too hot and eventually failing.

To help resolve this problem, Imperial Engineering recommends that e-compressors are inspected and serviced in accordance with OEM recommendations, whilst also taking a specific vehicle’s duty cycle into account. By ensuring the optimum maintenance frequency, including regular oil and filter changes, operators can increase e-compressor service life, as well as reduce the overall operating cost of the e-bus. The UK-wide distributor offers a range of upgrades and replacement assemblies for OEM e-compressors, as well as service kits and specialist synthetic compressor oil.

Imperial Engineering has a wealth of compressor system knowledge and is pleased to support operators with technical advice and guidance. For further information, please contact us.